ANCILLARY EQUIPMENT

Transform every boiler room equipment into a robust and efficient energy maker, custom-made to fit your steam or heating systems.

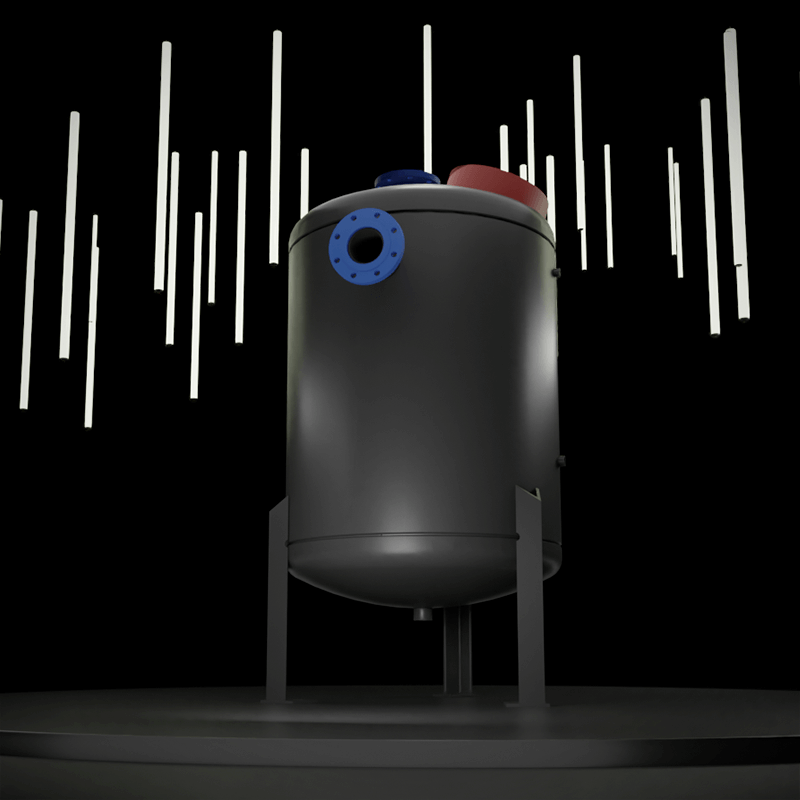

Maintain the efficiency of your steam boiler by discarding unwanted impurities in the water. Our range of blowdown tanks are designed in accordance with ASME Code (Section VIII, Division 1). They enable periodic and continuous high-pressure steam boiler blowdowns to lower water temperature to 65°C or less before sending it to the sewer system.

Water treatment greatly contributes to the performance of your steam generators . Regular chemical treatment increases your equipment lifespan and regulates the efficiency of your steam boilers. Simoneau Sterling offers high-calibre chemical solutions and technology to facilitate the water treatment management in your boiler room.

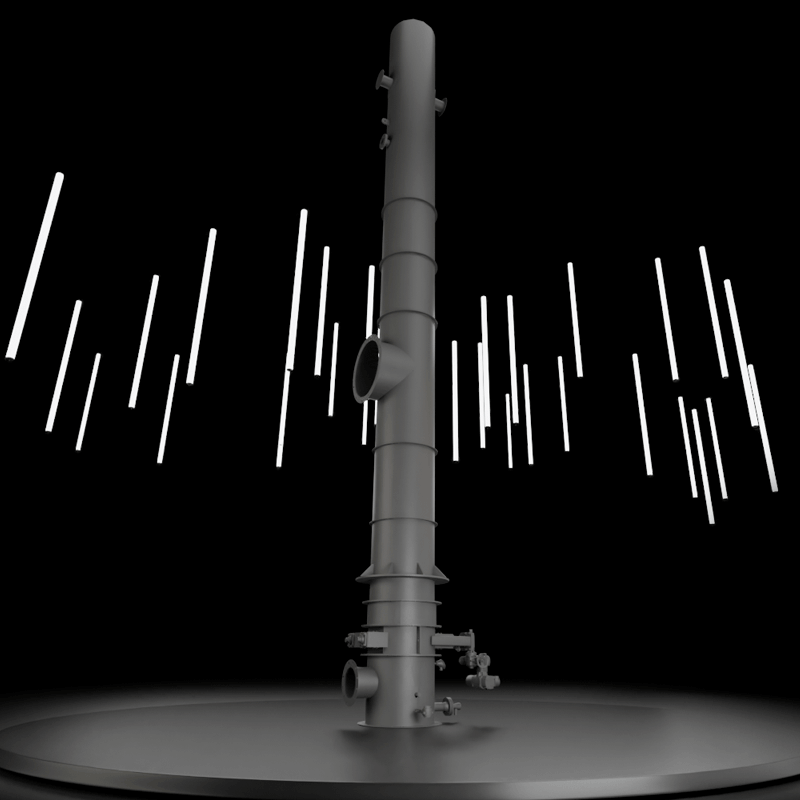

Develop or replace a chimney customized to fit your system. Whether you require a stainless steel or a carbon steel material, single or double wall chimneys, we carry the right product for every applications.

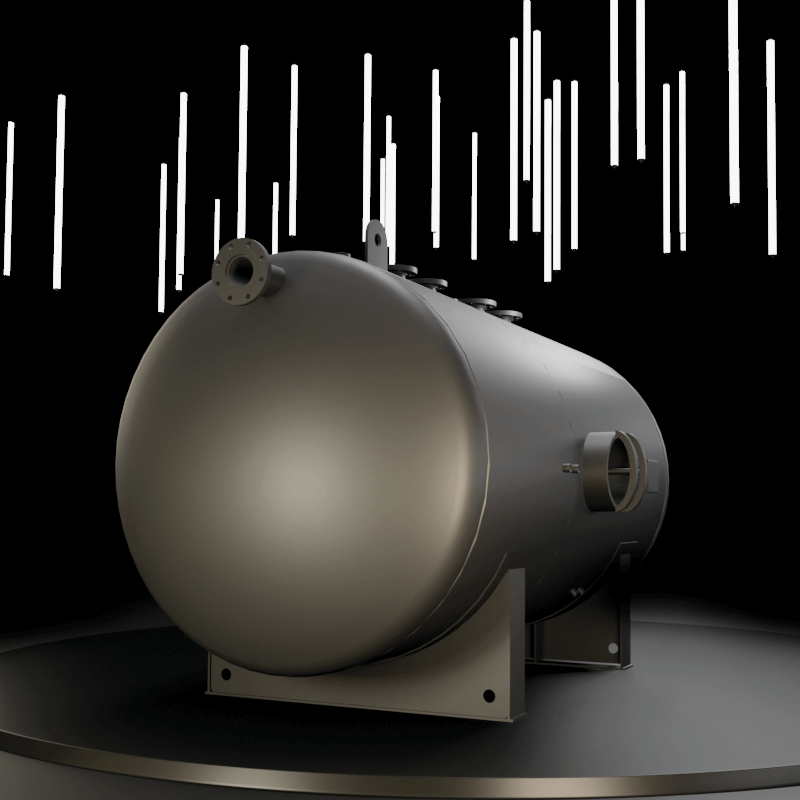

Condensate tanks recover condensate returns and add fresh water to meet boiler or deaerator water requirements. We offer a wide range of tanks well-adapted to your specific needs.

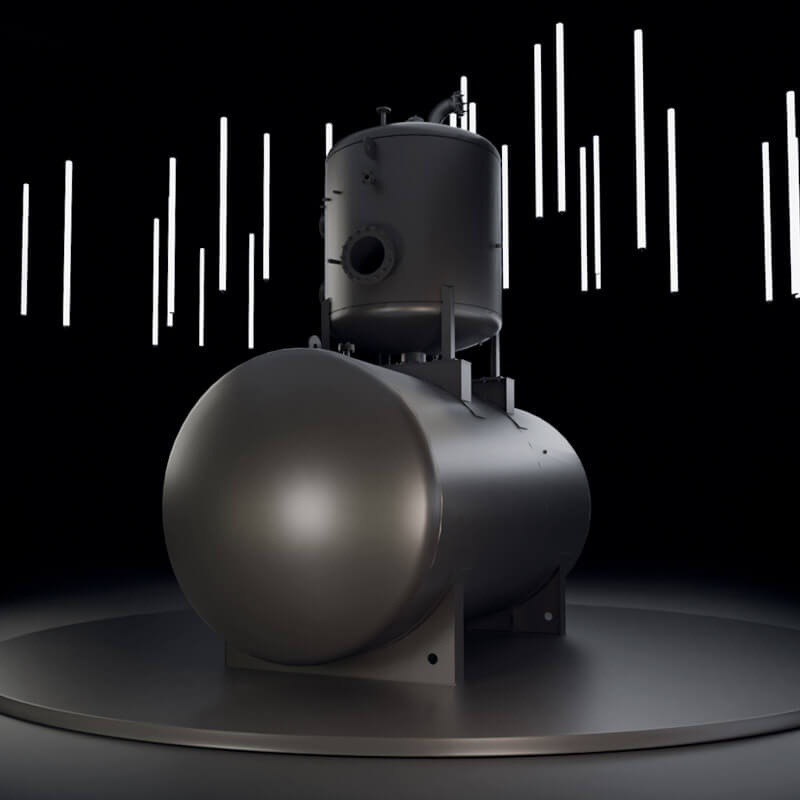

At Simoneau Sterling, we carry a thermal deaerator that functions as a water deaerating system and direct contact heat exchanger. Water is injected in a bath of steam in a counter-flow arrangement, allowing oxygen reduction to .005 ml/liter (7 PPB) and elimination of CO2. System heats water up to 228°F when operating at 5 psig.

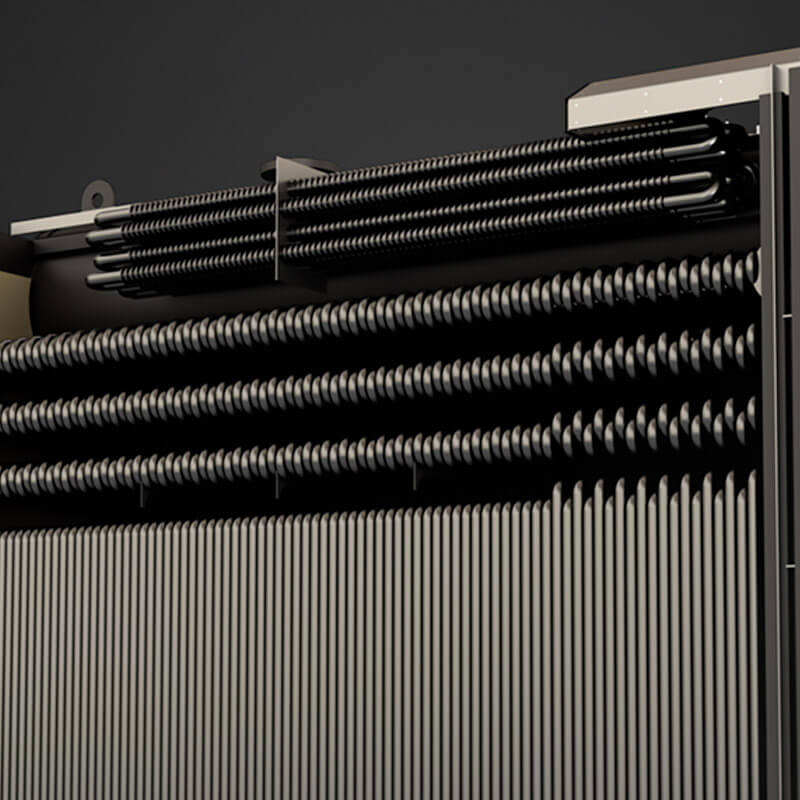

Reducing energy consumption is a key performance indicator of modern boiler rooms. We carry economizers that come in two designs.

- Bare tube economizers feature an inlet and an outlet header, connected by a bundle of bare tubes.

- Finned tube economizers share the construction of bare economizers. However, the tube fins are exposed to the hot flue gases, increasing the heating surface per linear foot of tubes and resulting in a more compact unit. The finned tube condensing economizer is built with stainless steel tubes and components

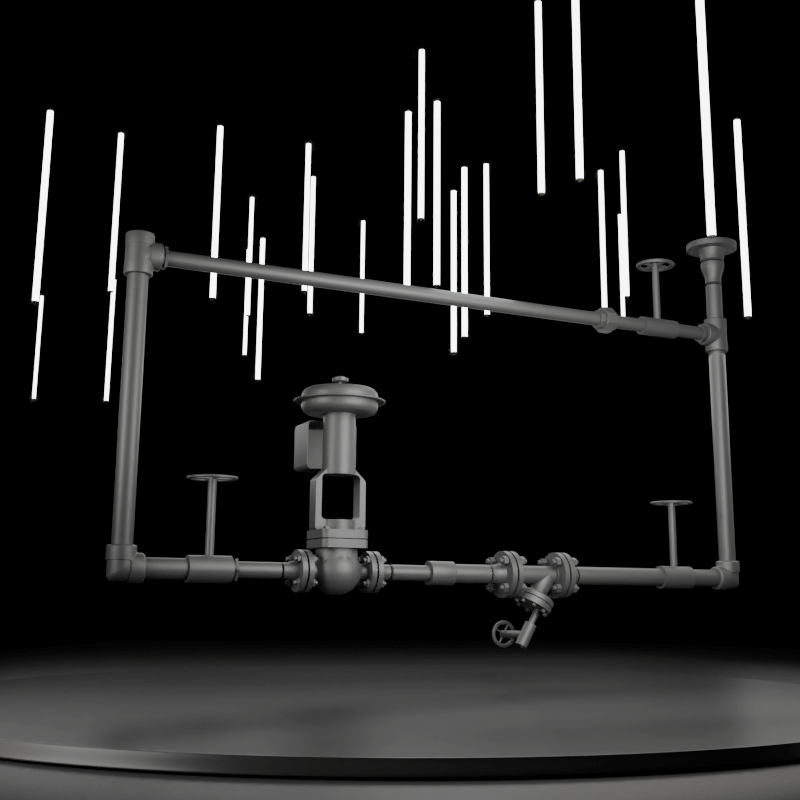

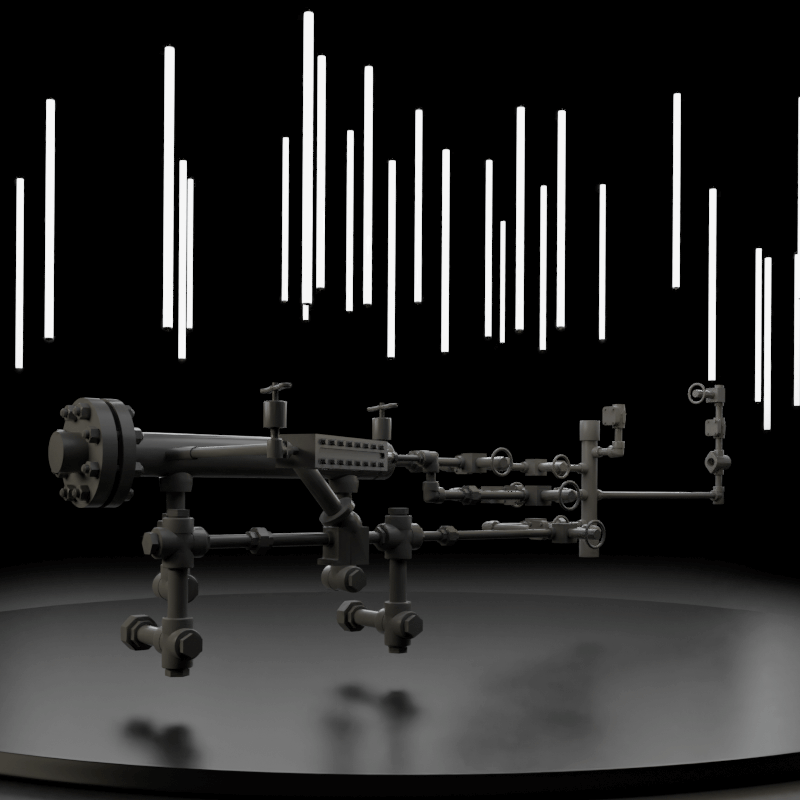

At Simoneau Sterling, we carry pumping stations to meet the clients needs, for both indoor and outdoor. We can provide you with turnkey skidded solutions that can tie in to your new or existing infrastructure, in accordance with all local and federal codes and regulations.

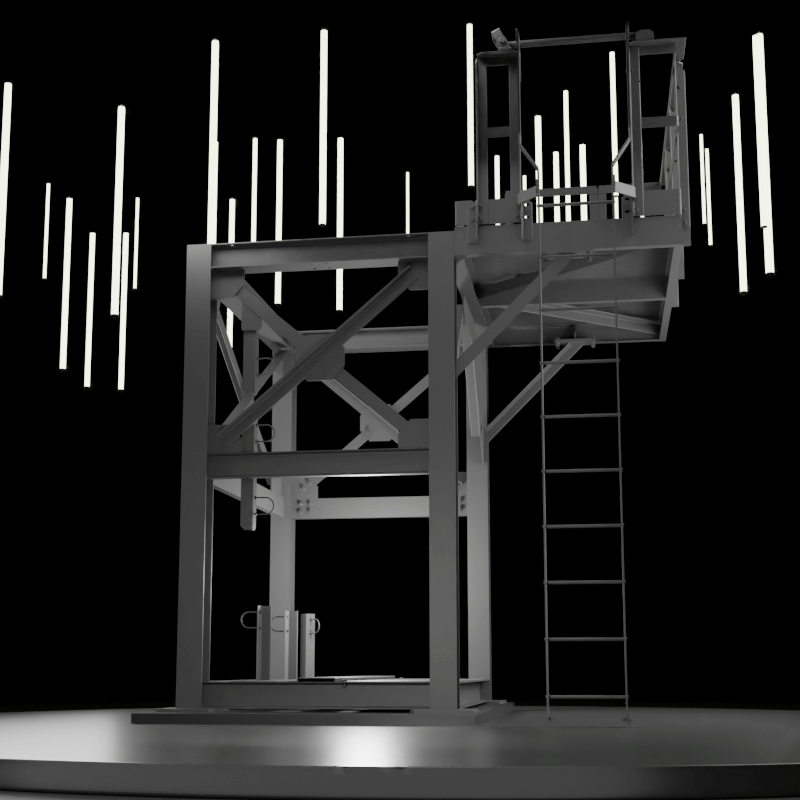

At Simoneau Sterling, we carry all structural steel framing components, including handrails, platforms and ladders that ensure safe access to your equipment. Structures are certified by structural engineers.

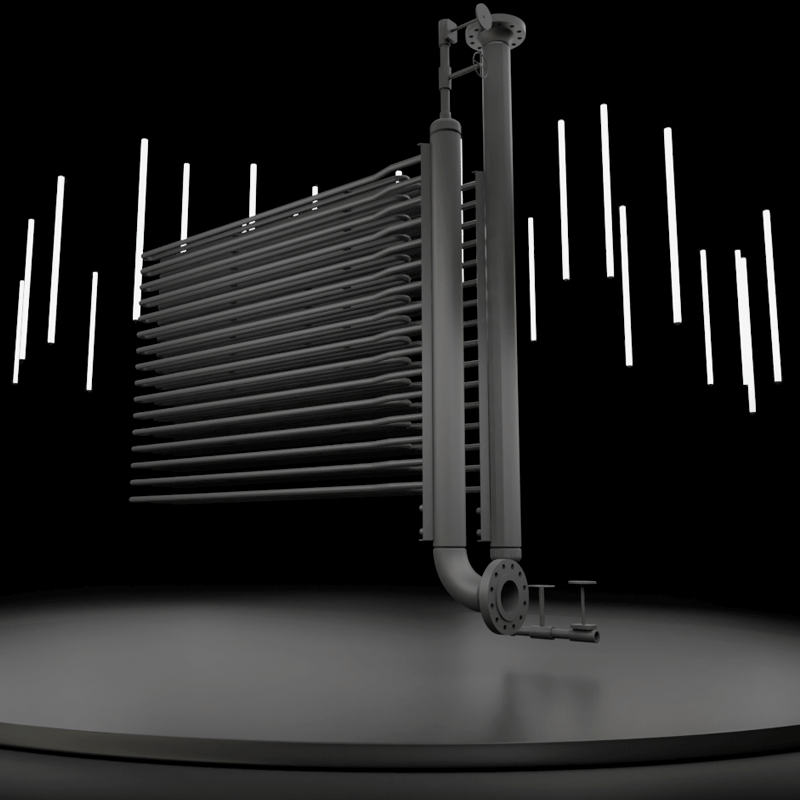

Increase your steam power plant efficiency with modern superheating technology. Convert your wet steam into a highly efficient dry steam. Our line of superheaters are designed as per ASME code section 1 using high quality tube materials such as SA213-T11 / T22. Tube diameters may vary from 1 1/4″ to 2 1/2″ depending on customer’s need.

Our range of water columns meet applicable ASME codes. They are electrode type and include water-level gauge glasses.